Right after accumulating a great deal of operational info (and checking the SOO) only then do we discover a path to insure the automation functions how it need to. The ultimate bit of That is examining the particular automation code or logic diagrams to ensure it really works proper.

The goal of the Excess fat is to make sure that the system works to the satisfaction with the service provider and the end-consumer.

Why It Matters: Combining instructions with Room for results makes sure clarity throughout testing and decreases the chance of lacking facts.

The purpose of the site acceptance test is to make sure that the site fulfills all the requirements from the client. This includes checking the operation in the site, the look, the usability, and the safety. After the site has long been tested and authorised via the client, it might then be launched.

“The undersigned certify that every one tests are already performed and verified According to the SAT document.”

Site acceptance tests are connected to manufacturing unit acceptance tests, in which they function by inspection and dynamic kinds of testing to method elements. The SAT (site acceptance tests) are created with the shopper themselves and this verifies the operation from the gear becoming tested.

Set via the GDPR Cookie Consent plugin, this cookie is used to history the consumer consent with the cookies during the "Ad" classification .

Although FAT verifies the performance in the PLC process in advance of shipping, SAT validates its functionality in the consumer’s operational context.

A Site Acceptance Test (SAT) is required to test a plant or machine provided by the maker. The SAT enables the customer to examine whether or not the requirements are fulfilled as well as equipment is useful. The SAT is used to simply accept the plant or equipment at The shopper's site.

Compile thorough documentation of SAT benefits and procedures for long run reference. Comprehensive the official handover on the PLC technique into the customer on productive get more info completion of SAT.

In the following paragraphs, we will take a look at many of the standard standard suggestions and methods that have to be regarded for doing an SAT.

To understand the primary difference is an actual world location, let’s look at an illustration of a undertaking where I did both of those the acceptance testing and practical testing.

As soon as the PLC system has reached the site, it is the career from the maker to perform SAT Together with the shopper website and handover it to them.

By conducting an SAT, good quality assurance is fulfilled, along with great production practice, Protected high-quality threat administration and efficient top quality Management checks.

Scott Baio Then & Now!

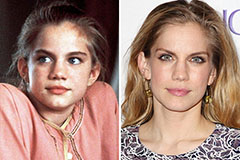

Scott Baio Then & Now! Anna Chlumsky Then & Now!

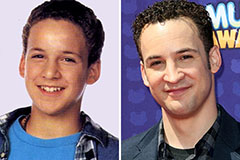

Anna Chlumsky Then & Now! Ben Savage Then & Now!

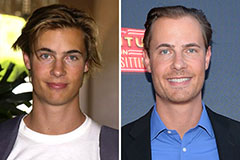

Ben Savage Then & Now! Erik von Detten Then & Now!

Erik von Detten Then & Now! Nicki Minaj Then & Now!

Nicki Minaj Then & Now!